China Supplier of Special Mechanical Standard Stainless Steel High Performance Roller Chain

The roller chain plays a crucial role in various industries, ensuring smooth and efficient power transmission. When it comes to selecting a reliable supplier for your roller chain needs, look no further than our company. With decades of experience and a commitment to excellence, we are the leading supplier of high-quality roller chains in China.

Product Description

Our roller chains are manufactured to meet the highest standards, making them ideal for applications that require durability, precision, and superior performance. Here are some reasons why you should choose our roller chains:

- We have been in the industry since 1991 and have established a strong presence both domestically and internationally.

- Our state-of-the-art production facilities cover an extensive area and are equipped with advanced machinery and tools.

- We have a skilled workforce of over 3,100 employees who are dedicated to producing top-quality roller chains.

- Our product range includes a wide variety of standard chains and special chains, such as A or B series chains, drive chains, conveyor chains, drag chains, and agricultural chains.

- We have obtained ISO9001, ISO14001, ISO16969, AAA, and API certificates, highlighting our commitment to quality and customer satisfaction.

Our agricultural chains are designed to meet the specific requirements of the agricultural industry. Some of our featured agricultural chains include:

- SH series high-strength heavy-duty short pitch roller chains

- SP series high-strength heavy-duty short pitch roller chains

- Walking tractor chains

- Combine chains

- ZGS38 combine chain with attachments

- Rice harvester chains

- Various agricultural chains with attachments

- S type steel agricultural chains

- S type steel agricultural chains with attachments

- A type steel agricultural chains

- CA type steel agricultural chains

- C type steel agricultural chains with attachments

- Special agricultural chains with attachments

Other Products

At EVER-POWER GROUP, we offer a wide range of industrial products to cater to diverse needs. Our product lineup includes:

- Agricultural Gearboxes

- Power Output Shafts

- Sprockets

- Fluid Couplings

- Worm Gear Reducers

- Gears and Racks

- Roller Chains

- Pulleys and Pulleys

- Planetary Gearboxes

- Timing Pulleys

- Bushings

We take pride in offering high-quality products at competitive prices. With our customer-centric approach, we strive to provide excellent service and meet our customers’ specific requirements. We welcome customizations based on drawings and samples to ensure that our products precisely meet your needs.

FAQs

- Q: How long has your company been in the roller chain industry?

- Q: What certifications have you obtained?

- Q: Can you customize roller chains based on specific requirements?

- Q: What industries do your roller chains cater to?

- Q: How do you ensure the durability and performance of your roller chains?

A: Our company has been in the roller chain industry since 1991, giving us decades of experience and expertise.

A: We have obtained ISO9001, ISO14001, ISO16969, AAA, and API certificates, underscoring our commitment to quality and excellence.

A: Yes, we welcome customizations based on drawings and samples to ensure that our roller chains meet your unique needs.

A: Our roller chains are widely used in various industries such as agriculture, manufacturing, automotive, and more.

A: We utilize advanced production techniques, high-quality materials, and rigorous quality control processes to ensure the durability and performance of our roller chains.

All the content of this page is from the Internet and is only provided as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in the content. Our replacement parts are suitable for after-sales replacement and can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory or supplier for purchase.

Performance Characteristics of Mechanical Chain

Mechanical chains possess several performance characteristics that make them highly efficient and reliable in various applications. Firstly, their sturdy construction ensures durability and the ability to withstand heavy loads. Additionally, mechanical chains offer excellent flexibility and can smoothly transmit power between different components. They also exhibit high resistance to wear, corrosion, and fatigue, ensuring a long lifespan. The precise design of mechanical chains guarantees accurate power transmission and minimizes energy loss. Furthermore, their low friction properties contribute to efficient operation and reduced maintenance requirements.

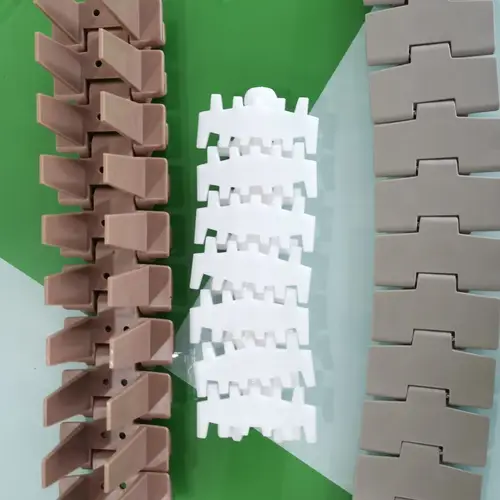

Types and Characteristics of Mechanical Chain

There are various types of mechanical chains available, each with its own unique characteristics. Roller chains, for example, are commonly used in industrial applications due to their high strength and load-bearing capabilities. Silent chains, on the other hand, are known for their noiseless operation and smooth power transmission. Leaf chains are ideal for applications that require compactness and high tensile strength. Each type of mechanical chain is designed to meet specific requirements, providing efficient and reliable performance in diverse applications.

Advantages of Mechanical Chain Made of Different Materials

Mechanical chains can be manufactured using different materials, each offering distinct advantages. Stainless steel chains, for instance, provide excellent resistance to corrosion and are suitable for applications in harsh environments. Nickel-plated chains offer enhanced wear resistance and are commonly used in industries where durability is crucial. Plastic chains are lightweight and exhibit self-lubricating properties, making them ideal for applications that require low noise levels and reduced maintenance. By selecting the appropriate material, the mechanical chain can be tailored to the specific needs of the application, ensuring optimal performance and longevity.

Application of Mechanical Chain in Various Industries

Mechanical chains play a vital role in numerous industries, highlighting their value and importance. In the automotive industry, they are utilized in engines, transmissions, and steering systems, ensuring smooth power transmission and efficient operation. In the manufacturing sector, mechanical chains are employed in assembly lines, conveyor systems, and robotic equipment, facilitating seamless movement and precise control. Agricultural and construction equipment heavily rely on mechanical chains for tasks such as lifting, towing, and power transmission. Conveyor systems in various industries utilize mechanical chains to transport materials efficiently. The widespread use of mechanical chains across different fields underscores their significance in ensuring smooth and reliable operations.

Future Development Trends and Opportunities

The future of mechanical chain products appears promising, with several development trends and opportunities on the horizon. Advancements in materials and manufacturing techniques are expected to enhance the performance and durability of mechanical chains. The increasing automation in industries opens doors for the use of innovative chain designs and technologies. Additionally, the growing demand for energy-efficient solutions presents an opportunity for the development of improved, low-friction mechanical chains. With continuous research and development, mechanical chains are poised for further advancements, catering to the evolving needs of various industries.

Choosing a Suitable Mechanical Chain

Selecting the right mechanical chain involves considering several aspects to ensure optimal performance and longevity. Firstly, determining the application requirements and the specific tasks the chain needs to perform is essential. Assessing the load requirements and understanding the maximum load the chain will encounter enables the selection of an appropriate chain with adequate strength. Evaluating the speed of operation helps in choosing a chain that can handle the required speed without compromising performance. Environmental conditions, such as temperature and exposure to chemicals, should also be taken into account when selecting a suitable chain. Finally, considering the chain type and size ensures compatibility with the application and efficient power transmission.

Summary

In conclusion, mechanical chains offer superior performance characteristics, making them indispensable in various industries. Their strength, flexibility, and resistance to wear and corrosion make them reliable for power transmission applications. The availability of different chain types and materials allows for customization based on specific requirements. Mechanical chains find extensive use in the automotive industry, manufacturing, agriculture, construction, and conveyor systems, highlighting their value in diverse fields. With future development trends and opportunities, the mechanical chain industry is set for significant growth and innovation. By carefully considering application requirements, load, speed, environmental factors, chain type, and size, one can choose a suitable mechanical chain that ensures efficient and reliable operation.

Author: Dream